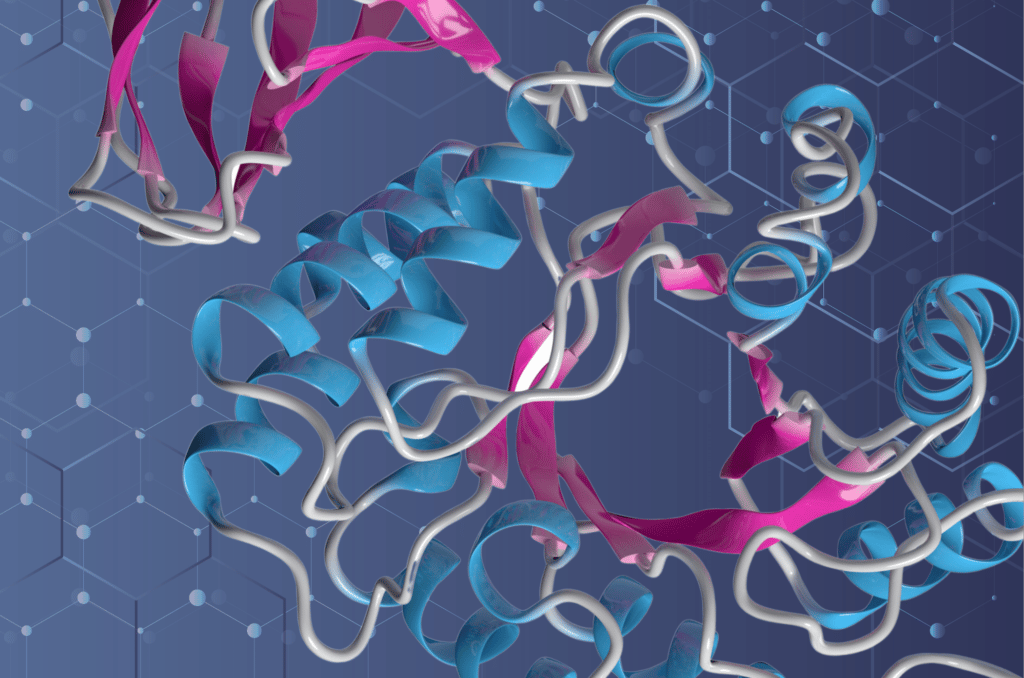

Allozymes technology is on the horizon of the fourth industrial revolution with it’s proprietary synbio platform, taking enzyme engineering to power the next level of sustainable development. As we embark on accelerating the sustainable future of industries, we have identified certain specialty ingredients focus areas in agri-foodtech sector, such as flavour, alternate proteins, upcycling waste into value-added materials, and designer fermentation for producing bioactives. Read on to see how our technology can be leveraged to address these markets.

Flavour:

Flavours are composed of specific chemical compounds, which can be produced through biological reactions involving enzymes. Our technology, working at 10x faster than competitor robotics labs, give us access to further information in shorter timeframes, expediting innovative solution development. With such a powerful platform, once we identify the enzymes responsible for the reactions, we can design, engineer, and screen for enzymes with desirable traits within a few months.

Plant-based products:

By studying the chemicals that re-create flavour and biopolymers (Eg:Starch) that drive texture, of meat, cheese, or egg, and the enzymes responsible for its synthesis, we can design the enzymes in-house and further engineer them to have improved enhanced functions, such as hyper-realistic textures and aromatic flavours. Our flexible technology can be leveraged towards a wide range of textures, flavours to serve diverse food cultures.

Agri waste and upcycling:

Lignocellulosic waste is one of the major agri waste generated from rice, banana, pineapple plantation and more. We are engineering custom enzymes to upcycle lignocellulosic waste into fiber-derived sugar to meet the growing demand for naturally-sourced sugar alternatives in a market worth 18.1 billion dollars. Our fiber-rich sugar would serve as a healthier alternative to the current sugar by upcycling waste as a form of sustainable sourcing.

Fermentation:

We leverage our expertise to analyse the natural pathway in tomatoes to eliminate the use of tomato skin needed for a cosmeceutical bioactive product. Through our enzyme discovery, we found the bioreactive ingredient needed to produce the cosmetics, and instead of leveraging natural resources and stripping them from the earth, we were able to mimic the pathway to produce and scale up the product more sustainably. When the enzymes were expressed in microbes, we could ferment the same ingredient more efficiently, sustainably, and faster than before to serve our customers.

The variations of enzymatic discovery pathways are endless, more than any robotics lab has touched before. Allozymes is proud to be a part of leveraging microfluidics technology to explore new pathways, generate new and more sustainable solutions to traditional manufacturing methods, and paving the way for a global paradigm shift in custom-designed enzyme engineering.